Galvanising

Which Protective Finish do I Need on my Brackets?

There are many ways of protecting metal from the weather. Common methods for protecting steel aerial support brackets include painting, zinc electroplating or passivisation and hot-dip galvanising.

Painting:

Painting can be the lowest-cost method but usually gives relatively weak protection. One industrial method for painting steel brackets is to immerse the component in a bath of 'paint' (a specialist coating formulation). This process may be proceeded by a de-greasing stage, followed by draining and drying, either naturally air-dried or accelerated by ovens.

Electroplated zinc and passivisation:

Electroplated zinc and passivisation ("zinc and pass.") provides good protection but with a fairly limited lifetime when used outdoors. Electroplated coatings are thin and will corrode away, typically in under ten years. Chromate passivisation is a chemical post-treatment that is nearly always used with electroplated zinc finishes. passivisation imparts the familiar greeny-yellow colour. Thinner passivisation can give a white or shiny finish; this looks cleaner when new but is less effective. Although passivisation improves corrosion performance in salt spray tests, it does not greatly increase the lifetime of a part such as an aerial bracket in typical outdoor conditions.

Hot-dip galvanising:

Hot-dip galvanising is the process of dipping steel components into a bath of molten zinc, following a chemical cleaning pre-treatment. The zinc reacts with the steel to form inter-metallic alloy layers, ensuring intimate metallurgical bonding between the substrate and the zinc outer surface. A galvanised zinc coating is very much thicker, possibly an order of magnitude thicker than a passivated electroplated zinc finish, and has a correspondingly longer lifetime.

Section 17 of the CAI Code of Practice for installing Terrestrial and Satellite TV Reception Systems states that hot dip galvanised brackets should always be used. This is for good reason; the installer will know that a good job has been done if dip galvanised products have been installed. A galvanised bracket or mount will always be considered to have superior protection compared to a painted or plated item. The use of inferior finishes inevitably leads to rusting once the coating has failed, which can lead to unsightly staining of brickwork and masonry, as is all too often seen!

Brackets/mounts that support a substantial amount of weight should, ideally, always be galvanised. Weld strength will be maintained, and the component's life span will greatly extend if the product is galvanised. The installer should recognise that a galvanised part is always the best choice, especially when considering the wind loading on a bracket/mount when the aerial or dish is installed.

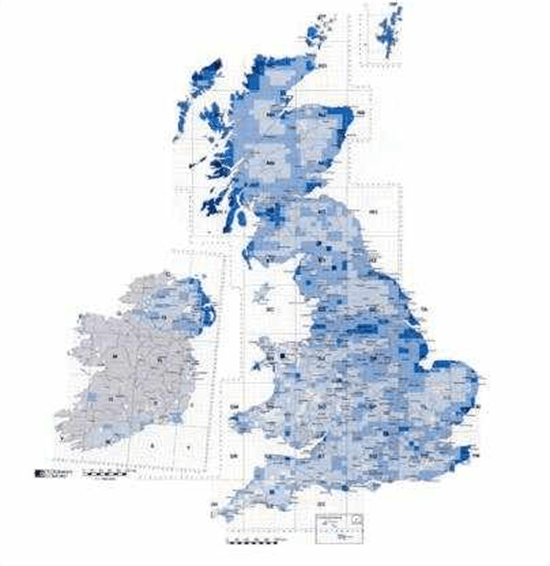

The following is a summary of the Zinc Millennium Map Project, which was an investigation into the background atmospheric corrosion rate of zinc coatings in the UK and Ireland

The Zinc Millennium Map Project

It is widely known that atmospheric sulphur dioxide (SO²) levels have been falling for several decades due to the changes in prime power source fuels. The result of the Zinc Millennium Map Project† demonstrates how the reduction in SO² levels since 1991 has helped to increase the life expectancy of hot dip galvanised coatings.

Hot dip galvanising, in conjunction with its many other benefits, including the lowest lifetime cost, reliability and coating toughness, is the most effective corrosion protection system available.

The table below shows the expected lifetimes for galvanised and electroplated zinc coatings for each of the five corrosion categories shown in the map.

Corrosion category |

1 |

2 |

3 |

4 |

5 |

Average corrosion rate ( mm/year) |

0.5 |

1 |

1.5 |

2 |

2.5 |

|

Life - galvanised 55mm |

110 years |

55 years |

37 years |

28 years |

22 years |

|

Life - zinc and pass. 8mm |

16 years |

8 years |

5.3 years |

4 years |

3.2 years |

|

Life - zinc and pass. 5mm |

10 years |

5 years |

3.3 years |

2.5 years |

2 years |

Data for painted finishes are not available.

Figures above are based on a typical 3mm steel product.

For further information please refer to http://www.galvanizing.org.uk/

Acknowledgements

- CAI (Confederation of Aerial Industries).

- The Galvanisers Association.

†Annual average atmospheric corrosion of zinc, UK and Republic of Ireland, 1998-2000.

Quick Add

Quick Add